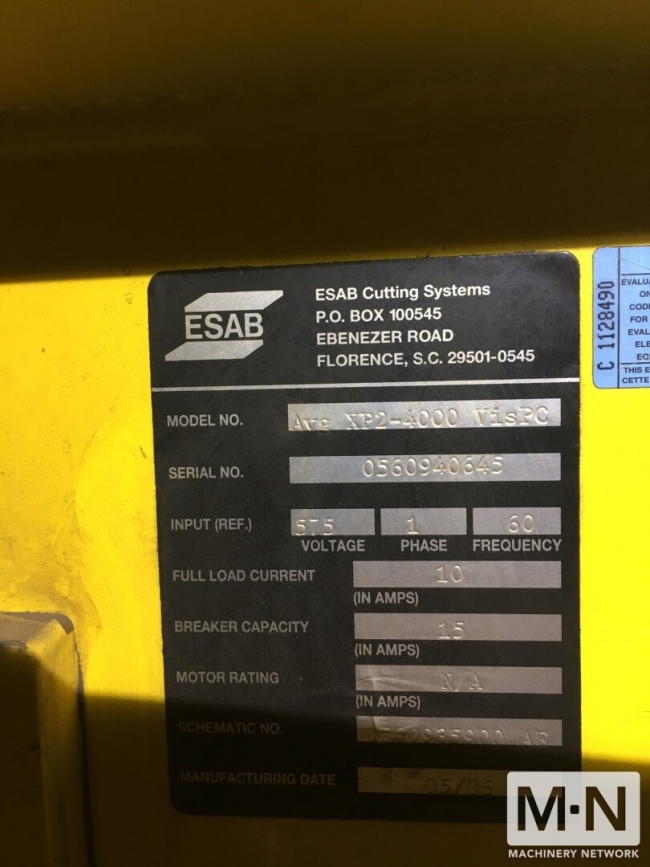

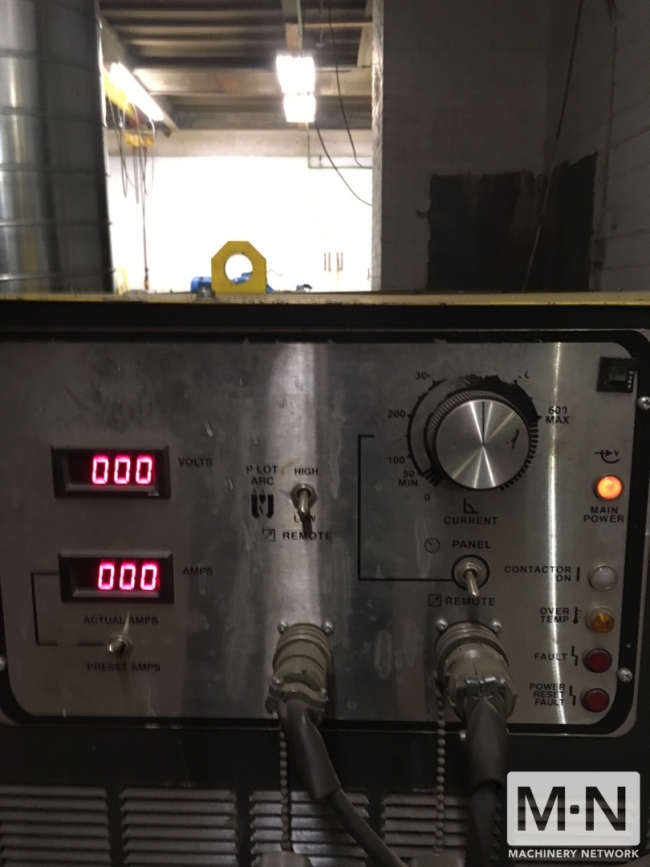

ESAB AVENGER XP2-4000

NEW 2004 RETROFITTED IN 2014

TEM QTY. DESCRIPTION PRICE (U.S.D.)

Retrofit to Upgrade the Avenger X with Serial Number 0560940645

This proposal contains the items necessary to upgrade the CNC

and Plasma system on the Avenger X.

The upgrades include

1) Vision T5 CNC

2) B4-200 High Speed Plasma Station

3) m3 Gas Control components for the plasma system using the

customer existing EPP-600.

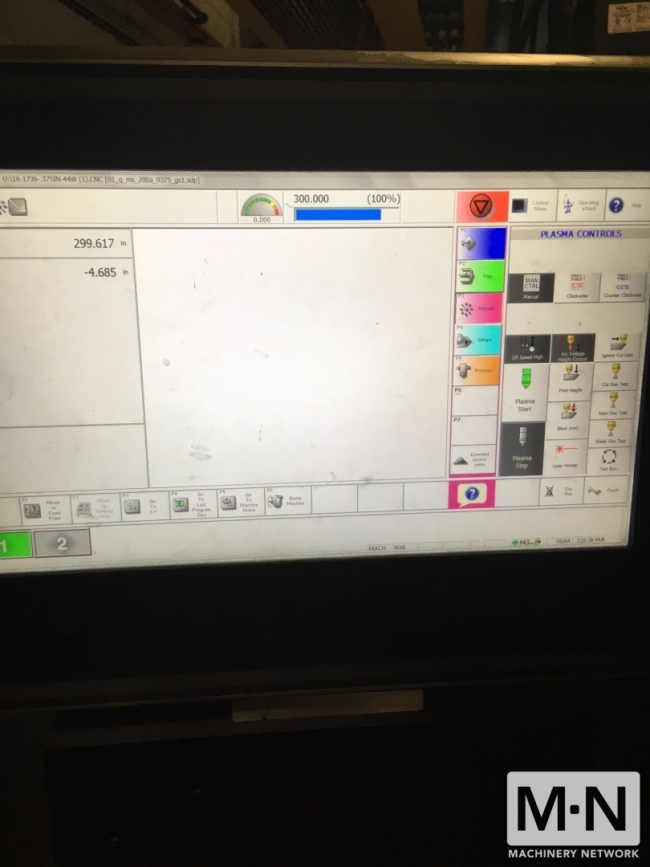

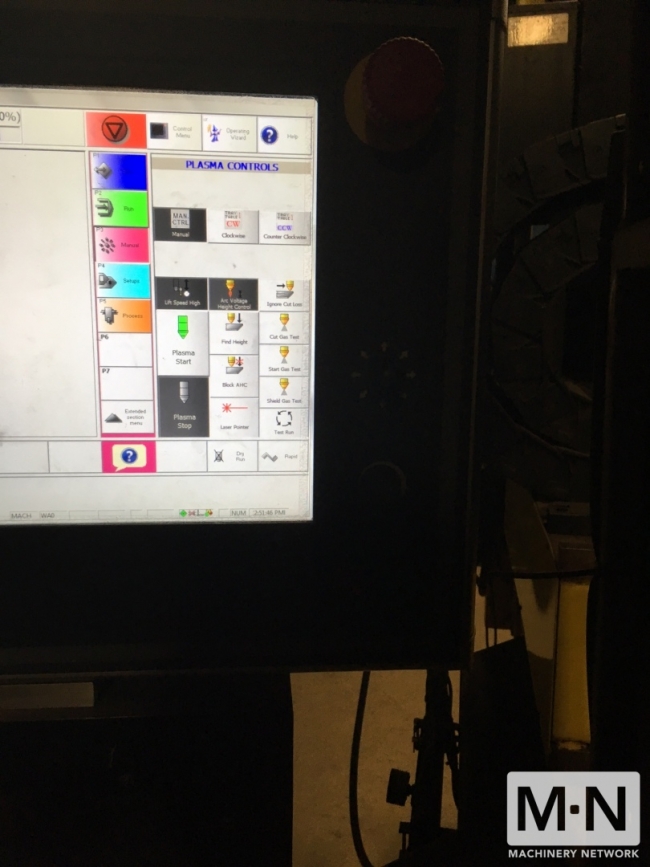

Vision T5 CNC System

Next Generation Cutting Machine Controller

- New Operating Wizard cuts training time in half

- New Process Selector reduces setup time

- Bright, wide, touch-screen features twice the display area

- Increased processing power for faster operation

The Vision T5 is a powerful, yet easy-to-use, CNC designed

specifically for shape cutting machines. Simplicity and ease of

operation are the core principles guiding the development of the

new Vision T5 touch-screen based control. From power-up to cut

part, the new OpWizard guides users with clear, step-by-step

instructions. New operators can be productive quickly by following

simple prompts with limited choices that lead from file selection to

starting the cut. Always have Instant access to the controls you

need for faster, easier operation. The Built-In Process Database

simplifies cutting tool setup by automatically setting parameters

such as cutting speed, kerf offset, and timers based on material

thickness, material type and cut quality desired.

- Windows® 7 Embedded provides a stable operating system

- Advanced Touch-Screen Interface for easier operation

- Built-In Process Database simplifies cutting tool setup

- Large, bright, 16:9 wide screen display

- True multi-tasking increases productivity

- The ergonomic panel layout means reduced operator stress

- Controls the most complex process tools

- Dual front panel mounted USB ports

- EasyShape Part Program Generator with 88 Shape Library

- Easily generate parts from DXF / DWG files

- Remote Diagnostics allows real-time testing & troubleshooting

3 1

4 1

5 1

ITEM QTY. DESCRIPTION PRICE (U..D.)

- 18.5" "Wide-Screen" Format Color LCD Touch-Screen

- Intel Mobile Processor for high performance with low heat output

- 250 GByte Mobile SATA Hard Disk Drive

- 1 GByte RAM, expandable to 4GByte

- 8 Position Joystick

- Speed Potentiometer

- Standard toggle switches for station up/down

- Integrated Ethernet (LAN) Port

- Built-in Software PLC

- CAN Bus I/O Controller

- Integrated Emergency-stop pushbutton

- Integrated Safety Key Switch for optional Safety Lockouts

- Controls up to 12 stations without add-on panels

- Operator Panel industrial protection rating IP54

Character Generator

For use with single point marking devices, such as scribes or

plasma markers. Allows machine to write characters on the plate

without having to program the motion for each character.

Characters to be marked are programmed in plain text, and can be

easily edited by the machine operator prior to marking.

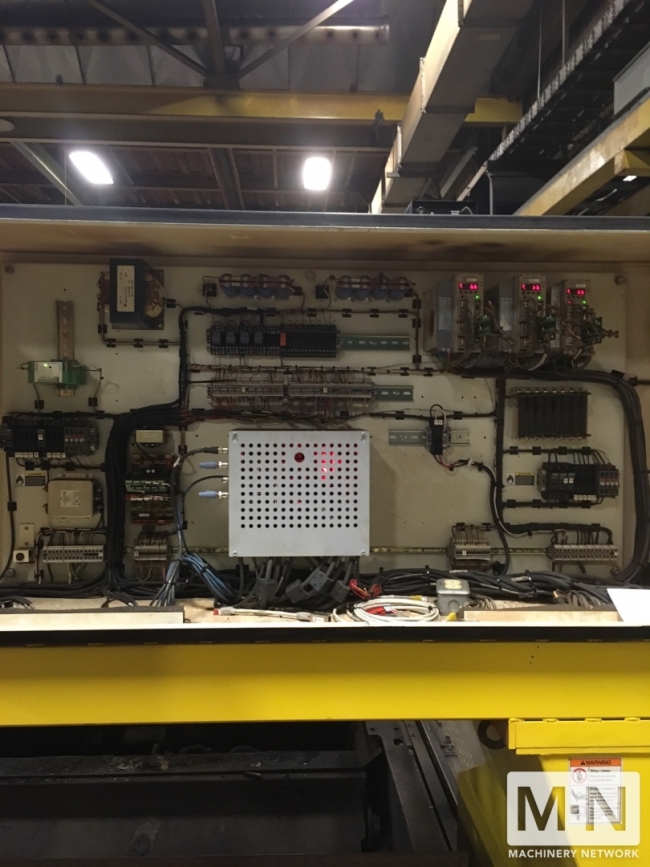

Update of Machine I/O Electronics to ACON

- required to allow integration of the m3 Gen 2 Plasma System to

the CNC control.

High-Speed Plasma Station (PB-MB-1)

with Smart Voltage Height Control

Programmable high-speed plasma torch station features the latest

advances in technology to deliver accurate height control,

automatic electrode wear compensation, and built-in torch

protection for dry or under-water precision plasma cutting and

marking.

Smart Voltage Height Control automatically adjusts the arc voltage

over the life of an electrode to maintain the correct cutting height,

improving cut quality and helping you maximize the life of every

electrode.

The Pneumatically Balanced tool-tip sensing allows the softest

possible plate-touch, and is backed up by electrical contact sensor

for clear-the-plate capability. After initial height is set, the device

clamps the torch tightly to the magnetic breakaway device, thereby

providing a stable torch mount with maximum protection in case of

tipped parts.

The lift also features a built-in encoder, allowing the Vision CNC to

precisely set the actual cutting height while cutting small holes,

ITEM QTY. DESCRIPTION PRICE (U.S.D.)

without relying on arc voltage. This is the most accurate way to set

the correct height for hole cutting, and maximizes hole accuracy

and concentricity.

Features Include:

- B4-200 Vertical Torch Lifter with 200mm Stroke

- High Speed Lifter Reduces Cycle Time Between Parts

- High-Accuracy Arc Voltage Height Control

- Dual Linear Rails provide Accuracy and Stiffness

- Magnetic Breakaway Crash Protection System

- Programmable torch height for optimum small hole cutting

- Pneumatically balanced initial height sensing

- Electrical soft-touch with clear-the-plate feature

ESAB m3 600 Amp Precision Plasma System With PT-36 Torch

(Using Customer Supplied EPP-600)

High Speed Cutting, Precision, Production Cutting and Plasma

Marking capabilities all from the same torch, selectable on the fly.

- Provides "Precision" cutting from 60 to 400 Amps

- Provides "Production" cutting from 60 to 600 Amps

- Pierce up to 2" thick Carbon Steel at 450 Amps Oxygen Plasma

- Cuts up to 3" thick Carbon Steel at 450 Amps Oxygen Plasma

- Cuts up to 1.5" thick Stainless Steel or Aluminum with 600 Amp

Nitrogen Plasma

- Sever up to 6" thick Stainless Steel or Aluminum with 600 Amp

Argon-Hydrogen (H-35) Plasma

Includes The Following:

- m3 Integrated Automatic Plasma Control System

provides electronically controlled plasma gas flow, start gas

flow, and shield gas mixing. All parameters are adjusted through

the Vision CNC, allowing full process automation using

Programmable Cutting Parameters (SDP Files). Uses

electronically controlled flow metering devices in a compact

design with no gears or motors.

- Patented PT-36 Torch With Torch Leads

- CC-11 Water Cooler/Recirculator with flow and level monitoring

- Start-Up Consumable Kit for the PT-36 Torch, including

Start-Up Supply Of Consumables for Oxygen and Nitrogen

Plasma Cutting up to 600 Amps.

- Input Bundle Including 4/0 Cables And All Applicable

Hoses And Cables Required With The System

Equipped with:

600 Amp Precision Plasma

(1) Oxy Fuel Torch

For further information please call Harvey Geller at 818-455-8103

Similar Machines

HAVE QUESTIONS?

You can also fill out the form below, and a representative will be in touch with you within one business day.

*All fields must be filled